The Geography of American Football

Friday, 7 April 2017

In this post I am going to talk about why American football teams are located where they are and why from time to time they move. Firstly to start off: unlike most sports teams, American football teams are called franchises which are generally owned by one person. However the league holds all the authority over these teams so they are very concerned about the profit that these teams make. The founding members of the National Football League (NFL) where the Decatur Staleys (now the Chicago Bears) and the Chicago Cardinals (now the Arizona Cardinals) .The Green Bay Packers were founded in 1919 and joined the NFL in 1921. The Packers are the oldest team in the league to be playing in the same location. As you can see from the picture the teams stretch across the country from Washington all the way down to Florida and New Hampshire.

Thursday, 6 April 2017

In this post I'm going to talk about the

geography of the ball itself. It’s quite unique in the sense that it is just

smaller than a rugby ball and has a line of laces down the middle on one side. Since 1941 Wilson has provide the NFL game ball and since

1955 those balls have been laced and branded in only one manufacturing plant in

Ada, Ohio. The only dedicated football manufacturing facility in the world pumps

out more than 700,000 balls each year. The ball itself is made out of a cowhide, not a

pigskin as the majority of people think. One cowhide results in ten footballs.

Each ball is constructed out of four panels sewn together. The lace is then

threaded through 16 holes. A rubber bladder is then inserted and the

ball is inflated to 13 PSI. According to the NFL, home teams are required to have 36 balls for outdoor

games and 24 for indoor games. Each ball is tested for appropriate pressure two

hours before the game. Twelve special balls, still in their box, are opened by

the officials and are only used for kicking. The balls are branded with a

"K" so they can be recognized as licking balls.

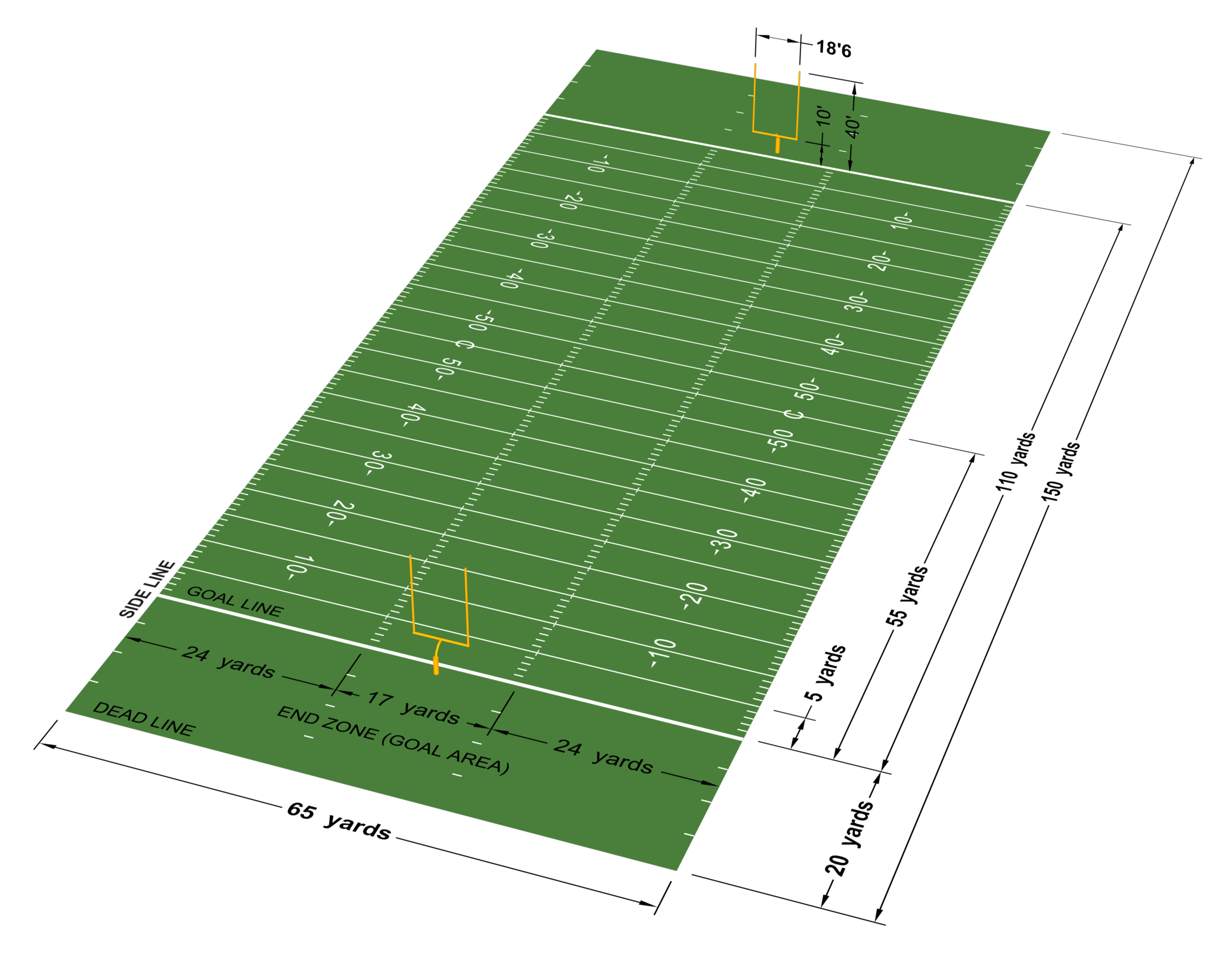

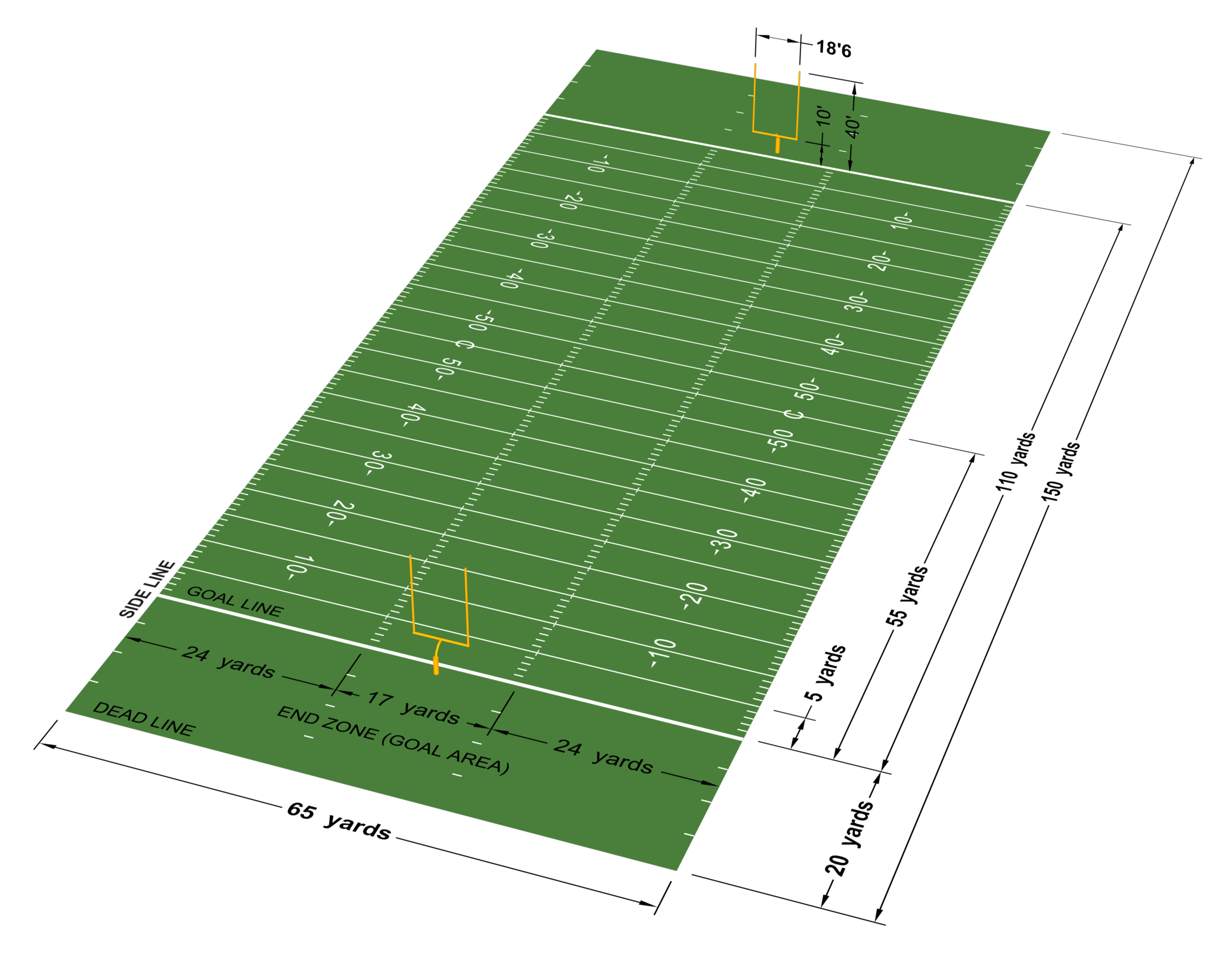

In this post I am going to talk to you about the field, how it is made and the different types.

Typically all American football fields are made of artificial turf however some people prefer to play on real grass. Normally an American football field is 160 feet by 360 feet. Official end zones are 10 yards deep and a 6 foot marked boarder shows the back of the end zone. Team benches are placed on the 30 yard line of either side of the field. Artificial turf is a surface of synthetic fibres made to look like natural grass. The main reason that people use this is for maintenance. Artificial turf stands up to heavy use, such as in sports, and requires no water or cutting. Covered and partially covered stadiums may require artificial turf because of the difficulty of getting grass enough sunlight to stay healthy. But artificial turf does have its downside. It has a limited life, it has to be cleaned from time to time, it is made using toxic chemicals, and its believed to be violating safety concerns.

Typically all American football fields are made of artificial turf however some people prefer to play on real grass. Normally an American football field is 160 feet by 360 feet. Official end zones are 10 yards deep and a 6 foot marked boarder shows the back of the end zone. Team benches are placed on the 30 yard line of either side of the field. Artificial turf is a surface of synthetic fibres made to look like natural grass. The main reason that people use this is for maintenance. Artificial turf stands up to heavy use, such as in sports, and requires no water or cutting. Covered and partially covered stadiums may require artificial turf because of the difficulty of getting grass enough sunlight to stay healthy. But artificial turf does have its downside. It has a limited life, it has to be cleaned from time to time, it is made using toxic chemicals, and its believed to be violating safety concerns.

Thursday, 23 March 2017

In this post I am going to talk about the manufacturing of the helmet. The helmet outer shell is constructed using a plastic called poly-carbonate alloy. The poly-carbonate alloy arrives at the manufacturing plant in pellet form—in boxes of thermoplastic pellets. The pellets are loaded into an injection-molding machine, melted, and forced into a mold the size of a football helmet. It takes about one minute to mold one shell. Shells come in small, medium, large, and extra-large sizes. Then, a multi-drill fixture drills 14-15 holes into the mold. Next they assemble air-liners to go inside the helmet. These air-liners inflate to make sure that the helmet fits correctly and helps in dispersing the energy of an impact. Other special liners contain special foams and elastic materials. Like air, these materials are designed to absorb energy and decrease the impact of a blow to the head. The foam-based liners are made in several pieces—one is for the back, neck, sides and top of the helmet. To make the special foams for the liner, large sheets of foam are cut to size. Then, a vinyl encasement is cut to size. A piece of vinyl is loaded into a vacuum former. The pieces of the foam are put into the vinyl and thermoformed to make an airtight seal. Another layer of vinyl is placed on top of the thermoform. Face masks are then attached. There are several different styles of face masks. The face masks are made out of steel wire and coated with plastic. There also are three different versions of plastic face masks. The chin straps are then attached and there you have an American football helmet

Subscribe to:

Comments (Atom)